About VG10 Damascus

VG10 Damascus is one of the knife class defined by the material and structure of the blade.

- VG10 is the name of steel made by Takefu Tokushu Steel Corporation located in Fukui Japan. VG10 has the characteristics that it has high hardness and does not rust easily, and is usually used as a Damascus knife cutting edge steel.

- Damascus blade is made by overlaying different steel layers. It has the property of being hardly bends and hard to break.

Comparison of VG10 and other steels

| Name of steel | Components |

| 440A steel | 0.40-0.50 of carbon, 18% of chromium |

| AUS6 steel | 0.50-0.60 of carbon, 13% of chromium |

| VG10 steel | 0.95-1.05% of carbon, 15% of chromium |

| AUS10 steel | 0.95-1.05% of carbon, 13% of chromium |

| Gingami#3 steel | 0.95-1.10% of carbon, 13.5% of chromium |

| Shirogimi carbon steel | 1.2% of carbon, 0% of chromium |

| Aogami super carbon steel | 1.45% of carbon, 4% of chromium |

In the past, it was said that if you want a sharp knife, choose a carbon steel knife, but it is easy to rust.

If you want rust resistant knife, choose stainless knife, but not very sharp like carbon steel knife.

However, VG10 is an ideal steel that combines the advantages of both steels. It is sharp like carbon steel and has strong rust resistant like stainless steel. (Hardness HRC 61, chromium 15%)

VG-10 is high carbon steel and also has strong rust resistant. Carbon is related to hardness, and chromium is related to rust resistant.

Learn more about Japanese steel

VG10 Damascus steel or Full VG10 steel

There are 2 types of vg-10 steel knives.

- VG10 Damascus steel blade; VG-10 cutting edge is sandwiched between layers of different steel.

- Full VG10 steel blade.

If you are looking for a good knife, vg-10 damascus steel knife is recommended.

The reason is explained in detail below.

Why VG10 Damascus steel knife is better?

Because VG10 Damascus steel will have various advantages (Compound characteristic) by composing multiple steel in layers. Followings are advantages obtained by overlaying steels.

- Heat treatment (hardening and tempering) can be easily. So it will be finished in a hard and sticky (flexibility) blade. The most important thing is the balance of hard and sticky (flexibility). If it lacks sticky (flexibility) hard blade breaks easily.

- Blade has the property of being hardly bends and hard to break. This is the same characteristics as a Japanese sword.

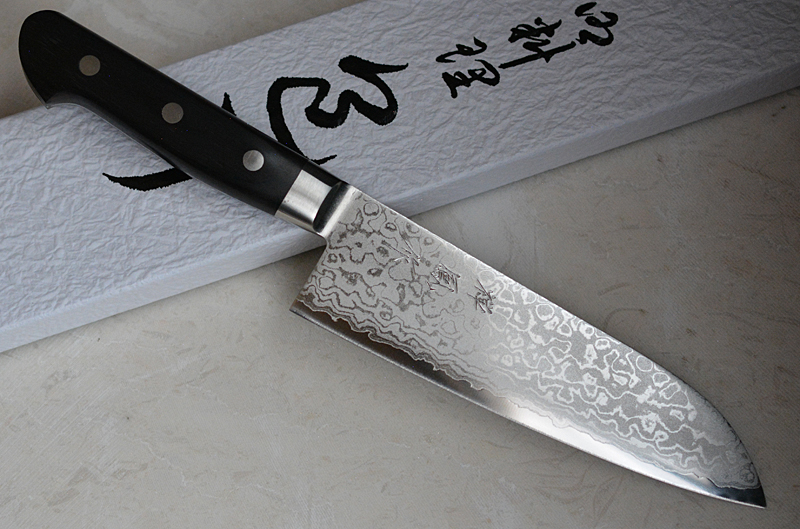

- Various patterns appear by overlapping multiple steels. This beautiful pattern is one of the charms of Damascus knives.

Recommended VG10 Damascus knives

Are there no better steels than VG-10 ?

Japanese steels that are often compared to VG10 are AUS10 and Gingami3.

The most popular steel is VG10, but AUS10 and Gingami3 also have similar properties. The characteristics of each one are explained below, so choose the knife that suits your needs.

AUS10 steel

AUS10 is a stainless steel made by Aichi Steel, which is also known as a steel manufacturer for Toyota Motor Corporation.

The advantage of this steel is that it is a little easier to sharpen with a whetstone than VG10.

And VG10’s chrome is 15%, AUS10’s chrome is 13%, so VG10 is a little more resistant to rust. But 13% chrome is enough so you don’t have to worry about rusting.

Gingami#3 steel

Gingami#3 is a stainless steel made by Hitachi Metals. (Hitachi Metals also manufactures all carbon steel in Japan, such as Aogami steel and Shirogami steel.)

It is easier to sharpen and a little easier to rust than VG10. (But it has 13.5% chrome so you don’t have to worry too much about rusting.)

Gingami#3 steel may be sharper than VG10. Since it is made by Hitachi Metals, it has properties close to carbon steel, and you can feel the sharpness like a carbon steel knife. (Even if the hardness is the same, different sharpness can be felt between stainless steel and carbon steel. Gingami#3 has a sharpness close to that of carbon steel.)

Aus10 and Gingami#3 steel knives